What are the Advantages of Heat Transfer Printing?

Relatively Inexpensive:

Compared with other forms of apparel printing like screen printing or embroidery, this method is cost-effective. Usually, if we have to achieve high-quality printing, it comes with a hefty cost. In the case of heat transfer printing, affordability takes precedence with utility. Therefore. this technique is the most feasible technique for high-volume custom apparel projects such as wholesale work uniforms, custom work vests, etc.

Low Minimum Quantities:

Typically, you will not be required to purchase a certain minimum quantity of items to place an order. For this reason heat transfer printing is widely used for applying names and numbers on team uniforms, where every jersey requires a separate print.

Quick Turnaround Time:

It is possible for this type of printing because there is minimal setup time.

Which Fabrics Work Best with Heat Transfer Printing?

If we talk about the fabrics compatible with heat transfer printing, we have to consider the heat resistance of those fabrics because of the high temperatures involved in this imprint method. Heat transfer works best with fabrics including cotton, wool, nylon, polyester, jacquard, and viscose. It's ideal for garment printing of your promotional giveaways, such as tote bags, t-shirts, and baseball caps.

The quality of heat transfer printing can vary drastically depending on the materials used and the printing techniques employed by printers. We're confident that we can offer you high-quality and long-lasting printed pieces. First, the items that are being printed are using premium transfer material. Then we apply using state-of-the-art printers, so the design is applied with care.

Various Types of Heat Transfer Printing

| Color Limited | Cost | MOQ | Setup Fee | Suitable Fabric | |

|---|---|---|---|---|---|

| Regular Heat Transfer | Full Color | Low | No MOQ | No Setup Fee | Most of Fabric |

| Sublimation Heat Transfer | Full Color | Low | No MOQ | No Setup Fee | Light-Colored Fabric |

| Special Heat Transfer | 1 Color | High | No MOQ | No Setup Fee | Most of Fabric |

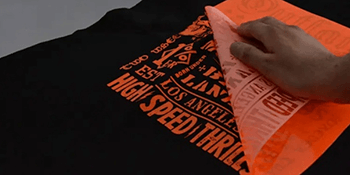

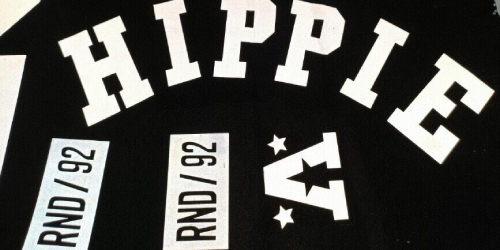

Regular Heat Transfer

Suitable for most fabrics, this method is moderately priced. There is no minimum order quantity or setup fee, and it supports full-color printing.

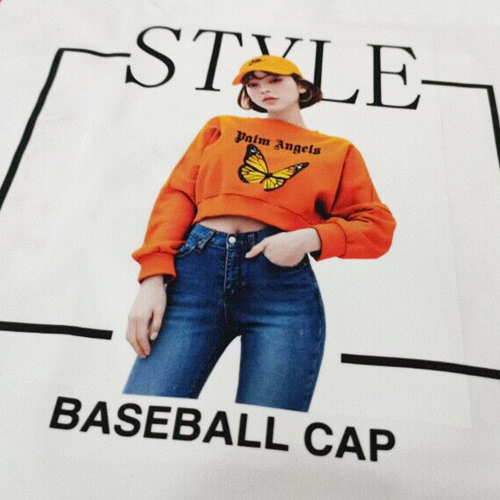

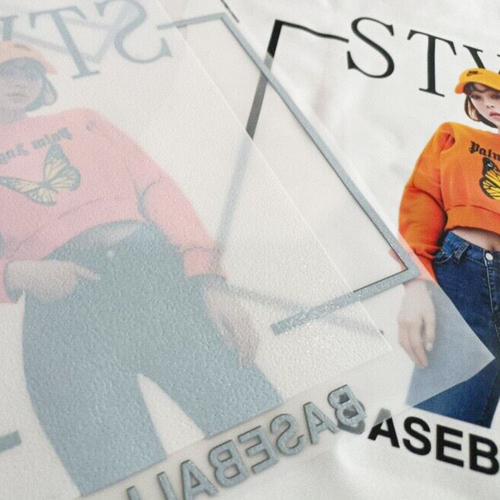

Sublimation Heat Transfer

This method provides vibrant colors compared to regular heat transfer. It can only be applied to light-colored fabrics containing polyester. There is no minimum order quantity or plate fee, and it is available at a lower price.

Recommended Custom Items for Sublimation

Clothing

Pillow Covers

Pouches

Scarves

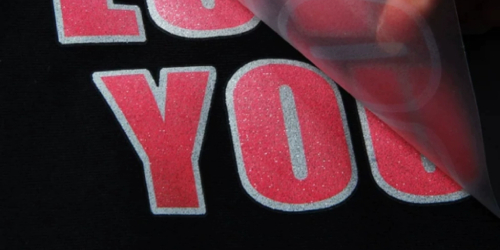

Special Heat Transfer

Special Heat Transfer, also known as engraved film, involves laser engraving patterns on special effect films. It offers effects such as luminous, glitter, and reflective properties. However, it can only be done in single colors, with limited color options for patterns and text. There is no minimum order quantity or plate fee, and it is suitable for most fabrics, but it comes at a higher price.

Luminous

Glitter

Reflective

Metallic Foil Printing

Multi Color Glitter